API Prosthetic Foot Design

This project delves into the design and prototyping of a prosthetic foot for the Accessible Prosthetics Initiative (API) club. As a club, our goal was to address the issue of prosthetic ankles having limited mobility. The human ankle has 6 degrees of freedom, whereas most commercial prosthetic ankles only have 1. By incorporating a novel design, we may provide amputees increased mobility and prosthetic functionality.

After being presented with this problem, I researched the bone structure, muscle structure, and shape of the ankle. The design inspired me to create a human-focused design. I started with a simple sketch and began rapid prototyping. Using the foam core skills I learned in my Medical Product Design class, I created the model below. This took 20 minutes and showed how the foot should move in plantarflexion and dorsiflexion.

The following day, I refined the design and created a 3D model. It consisted of 6 layers, which would be glued to one another, and four layers of 'bone' which would suspend the foot. A simple hinge joint would connect the structure, and the shape of the 'bones' would naturally prevent over-extension issues. I laser cut the pieces out of wood and built the foot, shown below.

To maintain the 'bone' structure's upright position, I attached two pieces of exercise band to the front and back of the ankle. This modification stabilized the foot, mimicking the function of the Tibialis Anterior and Gastrocnemius muscles. The success of this design solution caught the attention of my fellow peers. As a result, I was soon appointed as the Design Lead for the API club.

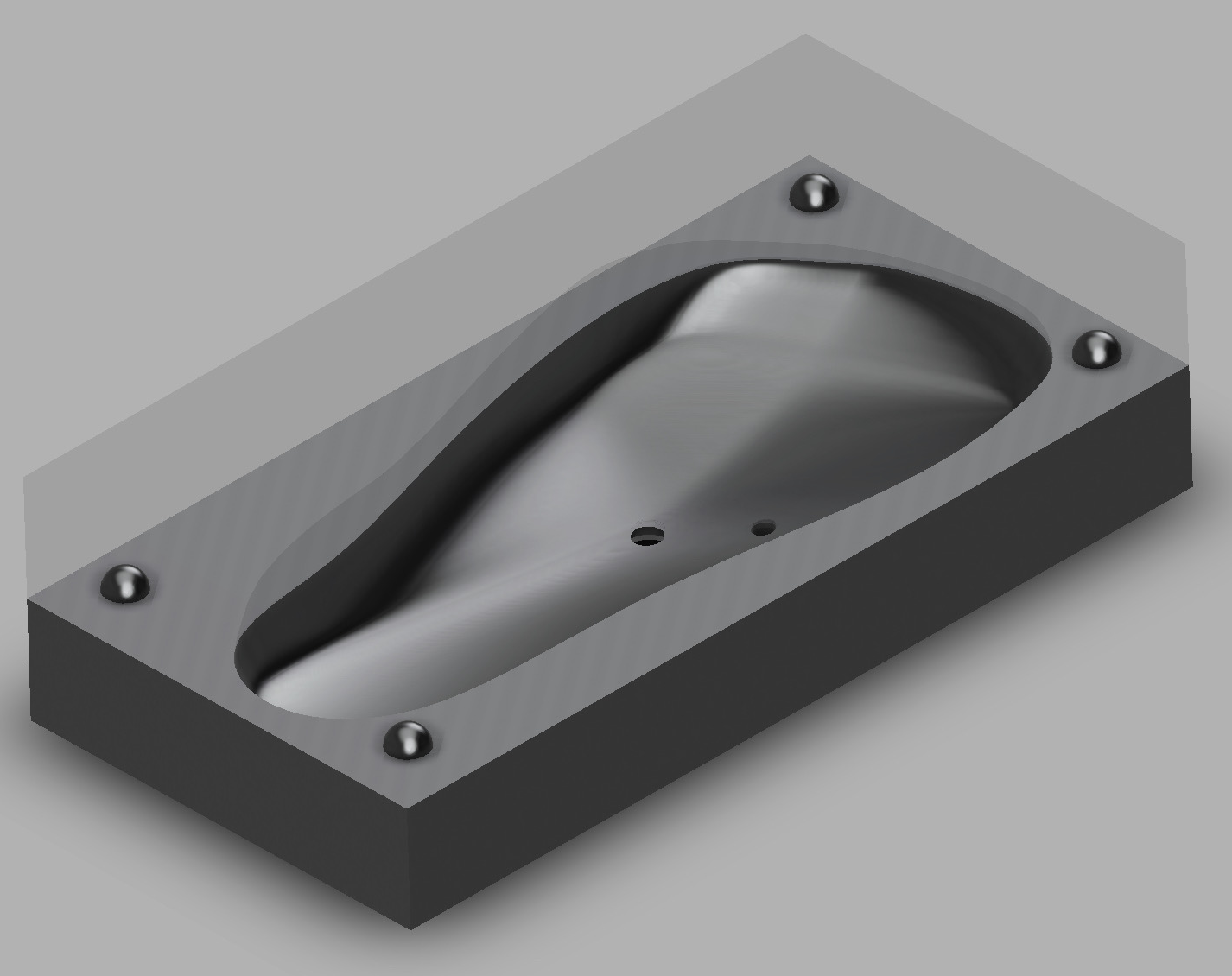

Before transitioning to other API-related projects, I aimed to explore two innovative concepts: developing a flexible sole prototype to enhance the foot's dynamic movement capabilities, and designing a refined 3D model for future use. Below are the designs I created using Fusion 360. I recently learned how to silicon mold in my Medical Product Design class and employed that skill to create the sole.

I created the final foot prototype using organic surface modeling, an advanced 3D design technique, in Fusion 360. This method allowed me to develop a prototype that's both functional and visually appealing.

I am grateful for the opportunities API has given me to widen my creative skillset and lead the team to innovative new solutions. I am excited to continue my journey with API, making an impact in the world of prosthetics.